Unusual equipment and technologies of water purification for home, village, town, city

Original production of drinking water in hydroautomatic self-backwashing plants DEFERUM, with polymer floating filtering media, successfully working in different countries

The hydro-automatic gravity filters Deferum for water purification, with floating filtering media (160,000 m3 per day for one million consumers)

We have recommendations from Coca-Cola, Pure water, the Malaysian Ministry of Health, the Housing and Utility Committee of Ukraine, from customers, partners and licensees from twenty-four countries

We are interested in contacts with the contractor, the licensee, the partner: (the lobbyist, the buyer, the designer, the subcontractor, the intermediary)

Our capabilities:

- Supply of factory water treatment equipment "Deferum", made of polypropylene or steel. Unusual removal of very high concentrations of iron, colour, odor, gases, radon, etc.

- Supply of container units Deferum (in 20 or 40-foot containers) for cleaning or post-cleaning of artesian water for supply to a cottage town, village, enterprise, apartment building

- Stationary construction of municipal wastewater treatment plants by our local contractor

- Reconstruction into existing water treatment facilities

- Commissioning

- Technical consultations

- Service support

- The business scheme of the BOOT (bilding, ownership, operation, transfer), ie financing, insurance, manufacturing, supply, construction, start-up, sale of water, management, free transfer of the water treatment plant to the municipality (after the parties fulfill the contract)

Our developer makes calculations based on the information from the questionnaire then offers the client a technical and economic proposal and draft contract, for negotiations

We suggest:

• Self-washed hydroautomatic filters and plants DEFERUM with a floating filtering media for cleaning underground artesian water, surface river water, storm water, industrial water.

Application: deferrization, deironing, demanganation, stabilization, removal of iron, manganese, turbidity, suspended particles, color, hydrogen sulphide, radon, carbon dioxide, odor, this is drinking water, industrial water, pre-cleaning, post-treatment, water treatment, water disposal, water cycle

• Serial Deferum-05 m3 per hour (i.e 2.2 gpm., i.e till 3200 gpd or 12 m3 per day) made of polypropylene, for periodic or continuous cleaning of artesian water, where there is a small or very large concentration of iron, odor, radon, color. Iron removal before reverse osmosis or ion exchange. If necessary: removal hardness for drinking water or a mineralization.

Deferum-05 operates in a cottage, in a hotel, in a hotel, in a settlement, in an apartment building, in an enterprise, as well as with other owners of artesian bore and water intakes to clean the source water from iron, manganese, hydrogen sulphide, ammonia, fluorine, boron, strontium, etc. concentrations. The protocols of the Moscow Test Center for Water Quality

The Deferum-05 pilot plant is always ready for testing and proof of the technology and equipment offered to the customer "Deferum"

• Aerodegasifier (aerator-degasifier), e.g aerator-degasifier for increasing pH of water

Application: intensive degassing of water, aeration, cavitation, reagent-free increase pH, redox potential and oxygen in water. Removal of dissolved gases (carbon dioxide, odor, hydrogen sulphide, methane, radon) from water

• Individual water treatment plants and stations

• Sale of licenses: "Transfer of know-how" for the independent business of the licensee

• Technical and technological reconstruction of water treatment plants in small, medium and large cities

• Short payback period of investments due to reduction of the cost of drinking water treatment, while maintaining the previous cold water tariff for consumers

"The tariff for drinking water is now the most reliable currency, because the monopoly tariff is always profitable!"

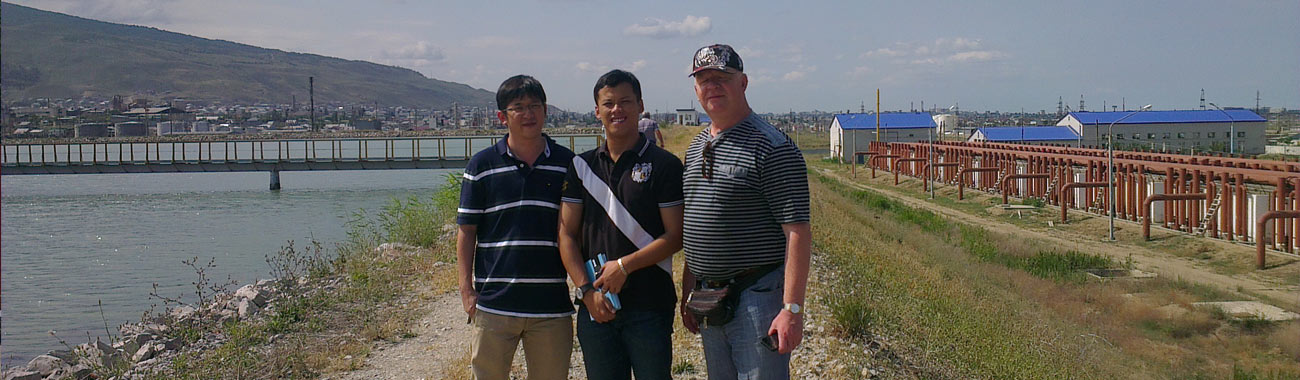

For example: "Self-cleaning river water 160 000 cubic meters. per day for one million consumers. " The tariff for consumers here is 4-6 times less than for other Russian utilities (see photo above)

Deferum installations are unusual and favorably different from alternative installations, because they do have relatively low capital and operating costs for water purification, because they work: without a building, without reagents, without electronics, without major repairs, without spare parts - reliably and for a long time

Our strategy:

• Construction and implementation of water treatment plants and installations of Deferum "on a turn-key basis", in different countries

• Participation with a licensee or a general contractor in local tenders Construction or supply of installations for cleaning artesian water or river water

More than 20 years patiently and persistently we work above that our offers, technologies and equipment were the best for buyer, customer, partner, licensee, intermediarie, lobbyist

Effectiveness of Deferum & Demagnum system in removal of high iron & manganese in groundwater source: here

We are ready for business negotiations and appreciate not only ours, but also your time

Skype: remizov2007 ; whatsApp, viber: +38 098 495 66 25 (Russian); +38 067 891 8191 (English)

Self-cleaning Plant Deferum for water purification. Unusual water purification without automation, without electricity, without reagents, without operator. Gravity flow from river to use